Refrigeration Explanation for Screw Compressor of Low Temperature Chiller Circulator

Because of the different compressors, the performance of the Niedertemperaturkühler circulators is also different. Screw compressors are different from piston compressors, and the structure is more precise. Therefore, if users need to choose the Niedertemperaturkühler circulators, they need to have their own understanding of their refrigeration operation.

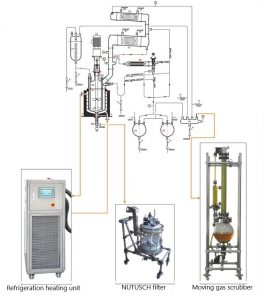

The screw compressor of the Niedertemperaturkühler circulator sprays lubricating oil into the working chamber when it works, which plays the roles of lubrication, cooling, sealing and silencing, as well as lubricating oil of main bearing, thrust bearing and shaft seal, pushing oil piston and balancing piston, after which the compressor is discharged by mixing with high-pressure gas.

Inhalation filter:

Inhalation filter of the Niedertemperaturkühler circulator is mainly composed of shell and metal filter. Install the suction thermometer, pressure gauge and oil valve on the shell. The oil valve is the refueling part of the unit when it is running, so more attention should be paid to it.

Oil cooler: Lubricating oil separated from circulating oil of the Niedertemperaturkühler circulator increases temperature (near exhaust temperature) because it absorbs frictional heat and heat of gas. High oil temperature and low viscosity will weaken sealing effect, increase internal leakage and reduce the efficiency of compressor. Therefore, lubricating oil must be cooled before it can be recycled. The circulating oil cooler of cryogenic water chiller plays the role of cooling oil.

Crude oil filter: In order to protect the normal operation of the circulating oil pump of Niedertemperaturkühler, the impurities are filtered through the crude oil filter before the lubricant enters the oil pump. For the first running machine, the cleanliness of the crude oil filter should be checked after the first running, and the filter screen should be disassembled regularly according to the cleanliness of the system. The filter can be cleaned with gasoline or kerosene and blown clean with dry air before continuing to use.

Verwandte Empfehlungen

-

Wie lässt sich das Problem des Ausfalls der Umwälzpumpe der Kühlanlage lösen?

1674Kühlung Heizgeräte sind in vielen chemischen, pharmazeutischen und Laboranwendungen erforderlich. Dann, wie das Scheitern der Kühlung Heizung Gerät zu lösen ist auch besorgt über, wie es zu lösen? 1. Ausfall der Umwälzpumpe Die Umwälzpumpe...

Details anzeigen -

Introduction to the quality and configuration of industrial refrigeration and heating circulators

1348With the development and progress of society, industrial refrigeration and heating circulators are used more in the industry, and the technological level is becoming more and more complex. So, what should users pay attention to after purchasing th...

Details anzeigen -

-

Precautions For Compressor Installation of the Screw Chiller Factory

1631When the operating conditions of the screw chiller factory restrict the compressor to be installed in a small enclosed space, its ventilation environment should be considered. It is necessary to add ventilation and exhaust equipment to facilitate ...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant