Die Methode, die kleine wassergekühlte Kältemaschinen beim Befüllen mit Kältemittel befolgen müssen

In our life, we believe that everyone is very familiar with refrigeration. In the central air conditioning and industrial production process cooling industry, kleine wassergekühlte Kältemaschine is more common. This unit is composed of a compressor in the fuselage, a horizontal shell and tube condenser, an evaporator, a thermal expansion valve, and some related parts. Under the cooperation of these auxiliary parts, the overall small water cooled chiller is compact in structure, convenient in operation and control, and is popular among the public in the market.

For refrigeration systems that do not have a high pressure reservoir and a low pressure vapor-liquid separator, the control of refrigerant charge is particularly important. Because the refrigeration system is a condenser and also acts as a high-pressure reservoir, the refrigerant is stored in the condenser, and the condenser is cooled. The heat dissipation area is reduced and the condensing pressure is increased, resulting in a decrease in cooling capacity.

For the control of the refrigerant charge of such small water cooled chillers, the following methods are followed during the filling process:

First, touch the temperature of the condenser casing.

The upper outlet of the condenser outlet is heated above the outlet, and the outlet below the outlet is cool. (There is a description of the high temperature exhaust of the compressor in the inside. The cooling indicates that the small water-cooled chiller is a liquid space.)

Second, look at the inspiratory pressure.

Corresponding to the temperature of the refrigerant water in the evaporator. (That is, corresponding to the evaporation temperature.)

Third, look at the compressor return pipe temperature.

The high-temperature unit return pipe should be cooled and dew, but it can be dew condensation to the compressor return valve; the low-temperature unit return pipe should be frosted, but the frost can be connected to the compressor return valve. If condensation or frost builds up on the compressor casing, liquid refrigerant will enter the crankcase, causing the compressor to run back and cause liquid problem.

Verwandte Empfehlungen

-

Kaltwassersatz der Serie KRY für die Qualitätsprüfung von Fahrzeugen mit neuer Energie

1009The new energy vehicle powertrain test bench can be directly connected to the power output end of the electric drive assembly through the half-shaft. The front end is equipped with high-precision torque sensor and speed sensor to provide high-pre...

Details anzeigen -

How to install -50 °C cryogenic unit manufacturers equipment?

1047-50 °C cryogenic units are used in the refrigeration and chemical industry, so what issues should be paid attention to during installation? LNEYA professional manufacturers tell you that you should install according to the instruction manual. For...

Details anzeigen -

Simulation analysis and result analysis of battery pack thermal management

1030battery pack thermal management simulation analysis

Details anzeigen -

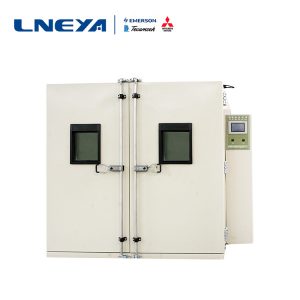

Beschreibung der Merkmale der begehbaren LNEYA-Prüfkammer

832Einzigartige ausgewogene Temperaturregelung Methode, eine stabile und ausgewogene Heizleistung kann für eine hohe Präzision und hohe stabile Temperaturregelung verwendet werden.Die Temperatur, die von der Temperaturanzeige angezeigt wird,...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant