Low-temperature coolant circulation pump used with rotary evaporator

The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the chemical industry is becoming more mature. As a laboratory instrument, cryogenic coolant circulation pumps are indispensable to the laboratory field. It plays an important role in chemical, pharmaceutical and chemical research.

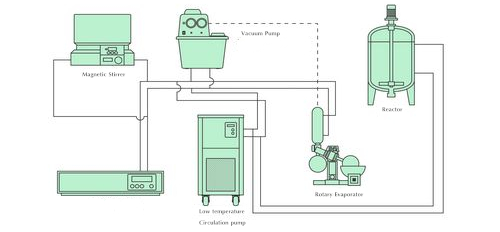

The low-temperature coolant circulation pump can directly cool test tubes, reaction flasks, etc. to carry out chemical reactions at low temperatures, and carry out low-temperature storage of chemicals and biological products. It can also be used in conjunction with rotary evaporators, vacuum freeze-drying boxes, circulating water-type multi-purpose vacuum pumps, etc.

One low temperature coolant circulation pump with two rotary evaporation laboratory cases Note points:

When in use, the actual temperature should not be lower than the minimum temperature. If water is used as the circulating solution, the water inlet pipe cannot be higher than 60 degrees Celsius, but when using absolute ethanol, the water inlet can not be higher than 10 degrees Celsius.

Lneya low-temperature coolant circulation pump adopts international brand compressor, which has small volume and high efficiency. Single compressor can achieve -152°C temperature control. The shell material is cold-rolled steel plate, and the circulating pump with pressure ≤6bar can be customized to make the liquid storage larger capacity according to the needs. Exclusive self-cascade supercooling refrigeration technology, in order to save water resources, can use ethylene glycol-water mixture for circulating refrigeration, strict circulation pipeline design, prevent circulating water pollution, extend the circulating water use time; -125 ° C ~-20 °C Wide temperature range; adjustment unit 0.1 degree. Ambient temperature monitoring function is provided to prevent damage to the system when the ambient temperature is too high.

Verwandte Empfehlungen

-

Effect Of Humidity On Laboratory Chillers

1023The high humidity reduces the insulation strength of the electrical equipment of the chiller in the laboratory. The moisture in the air adheres to the surface of the insulating material to form condensation, which reduces the insulation resistance...

Details anzeigen -

Test instructions for refrigeration heating temperature control system for fuel oil test

1173The refrigeration heating temperature control system can be tested for different projects during operation. The detection of different projects is different. Among them, the refrigeration heating temperature control system for fuel oil testing is ...

Details anzeigen -

Überlegungen zur Auswahl eines Temperaturregelungssystems für die Destillation

1295Das Lneya Destillationssystem-Temperiersystem ist ein selbst entwickeltes Kälte-Heizungs-Temperiersystem für die Destillationsindustrie, das in der Destillationsindustrie sehr begehrt ist. Was also sollte...

Details anzeigen -

Introduction of distillation principle and temperature cycle control device

962Distillation is a common method for purifying liquid substances and separating mixtures. The boiling point of the compound can also be measured by distillation, so it also has a certain significance for the identification of pure liquid organic co...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant