Nachrichten

Temperature control range and accuracy of high and low temperature tester

The temperature control accuracy of heat transfer oil medium of the high and low temperature tester used for component testing is plus or minus 0.5 ℃, which solves the problem of temperature control lag in electronic components. Main advantages of temperature simulation system of high and low temperature tester: 1. Temperature control accuracy: ± 0.5 ℃ 2. Real time monitoring of the real temperature of the components to be tested 3. For a single IC (module) among many components on PCB, high ...

Details anzeigen

Merkmale und Vorteile von luftgekühlten Kaltwassersätzen

1. Configuration of air-cooled chillerAir cooled chillers can be divided into air-cooled vortex chillers and air-cooled screw chillers according to the type of compressor. The air-cooled vortex chiller is mainly composed of vortex compressor, evaporator, condenser, refrigeration element, circulating water pump, stainless steel water tank and original imported fan electric control system. The air-cooled screw chiller is composed of screw compressor, evaporator, condenser, refrigeration compone...

Details anzeigen

The main purpose of the reactor heating and cooling system

The reaction kettle heating and cooling system is suitable for high-purity metals, rare substance purification, laboratory environment simulation, magnetron sputtering, vacuum coating and other industries. The large-scale cryogenic pump unit can provide a cooling environment for laboratory instruments. The heating and cooling system of the reactor is a low-temperature liquid circulation equipment that adopts a mechanical shape for refrigeration. It has the function of providing low temperatur...

Details anzeigen

Environmental Conditions for Installation of Air Cooled Chillers

As we all know, the installation of most machines needs to match the environment and conditions. Of course, our industrial air-cooled chillers are no exception. If the air-cooled chiller is not installed for the first time, it will bring a lot of inconvenience and loss to the later industrial production! For example, if the chiller is not installed smoothly, it will cause abnormal operation of the chiller, resulting in noise, water leakage and even having to shut down for maintenance. It may ...

Details anzeigen

Neue Energieprüfmethode und Anwendungsfall eines Temperatursimulationsthermostats

LNEYA new energy vehicle battery high and low temperature cycle test is one of the most widely used equipment in modern vehicle battery testing. Lithium battery is one of the more common batteries. What should be paid attention to when using it? Application introduction: The temperature simulation thermostat system is also called high and low temperature cooling test machine/new energy test thermostat. It consists of a refrigeration compressor unit, a cold storage box, a heat exchange contai...

Details anzeigen

Strukturelle Merkmale von industriellen Rückkühlern

In the chemical reaction, there are strict requirements for the reaction temperature. It is necessary to raise the temperature to an appropriate temperature to carry out the chemical reaction smoothly. After the reaction, the temperature in the reactor must be reduced to room temperature. The existing heating system of the reactor is relatively simple, so the process of reducing the temperature in the reactor to room temperature takes a long time, and the thermal energy can not be used reason...

Details anzeigen

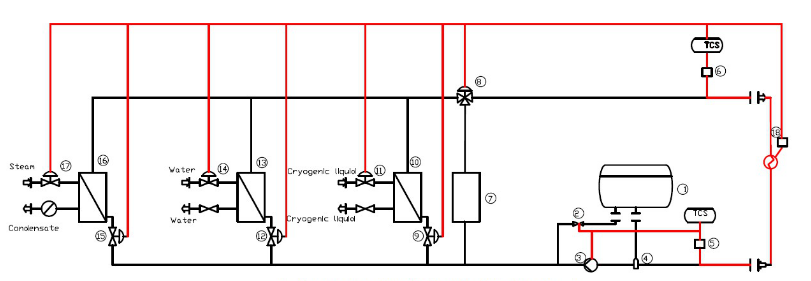

Prozesssteuerungssystem für die chemische Synthese Temperatursteuerungssystem TCU

Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software and application software interface. It has good flexibility and scalability, and meets the requirements of continuously improving production scale for measurement and control ability. Security: the system has a permission mechanism to realize multi-lev...

Details anzeigen

Was sind die wichtigsten Punkte für die regelmäßige Wartung des Rückkühlers?

Rückkühler werden in der Industrie häufig eingesetzt, und die wärmeerzeugenden Teile verschiedener Geräte erfordern Rückkühler, so dass die Betriebseffizienz sehr wichtig ist. Während der Betriebszeit des Rückkühlers muss regelmäßig überprüft werden, ob der Anschluss der Kühlwasserleitung sicher und fest ist. Ob der Durchfluss, die Temperatur und der Druck des Kühlwassers angemessen sind, um die Kühlwirkung des Rückkühlers nicht zu beeinträchtigen, wenn das Wasser f...

Details anzeigen

Wann sollte man sich für ein TCU-Temperaturkontrollsystem entscheiden?

Zunächst einmal muss man wissen, dass der Reaktionskessel im Allgemeinen die notwendige Temperaturkontrolle zusammen mit der chemischen Reaktion des Materials selbst durchführen muss. Durch die Temperaturänderung des zirkulierenden Mediums im Mantel oder in der Spule wird die Temperatur des Materials so gesteuert, dass die Zieltemperatur des Materials erreicht wird. Für die Temperaturregelung von Reaktionskesseln in der chemischen und pharmazeutischen Industrie ist die Auswahl der Temperiergeräte...

Details anzeigen

Vier wichtige Punkte bei der Installation einer wassergekühlten Kältemaschine

Die Installation einer wassergekühlten Kältemaschine kann unter vier Gesichtspunkten erfolgen: zunächst die Installation der Kältemaschine, dann die Installation der Wasserleitung, die Reinigung der Wasserleitung und die Isolierung der Ausrüstung. Unterschätzen Sie nicht die Installation dieses Teils, die sich direkt auf den sicheren und stabilen Betrieb der wassergekühlten Kältemaschine auswirken wird. Hier sind vier wichtige Installationspunkte. 1. Installation von wassergekühlten Kühler (vor allem Stiftung Anti-Vibrations-Gerät)Wir alle wissen, dass eine flache und geräumige Platz...

Details anzeigen LNEYA Industrial Chillers Manufacturer

LNEYA Industrial Chillers Manufacturer