Nachrichten

Description of industrial grade SUNDI heating and cooling temperature control system

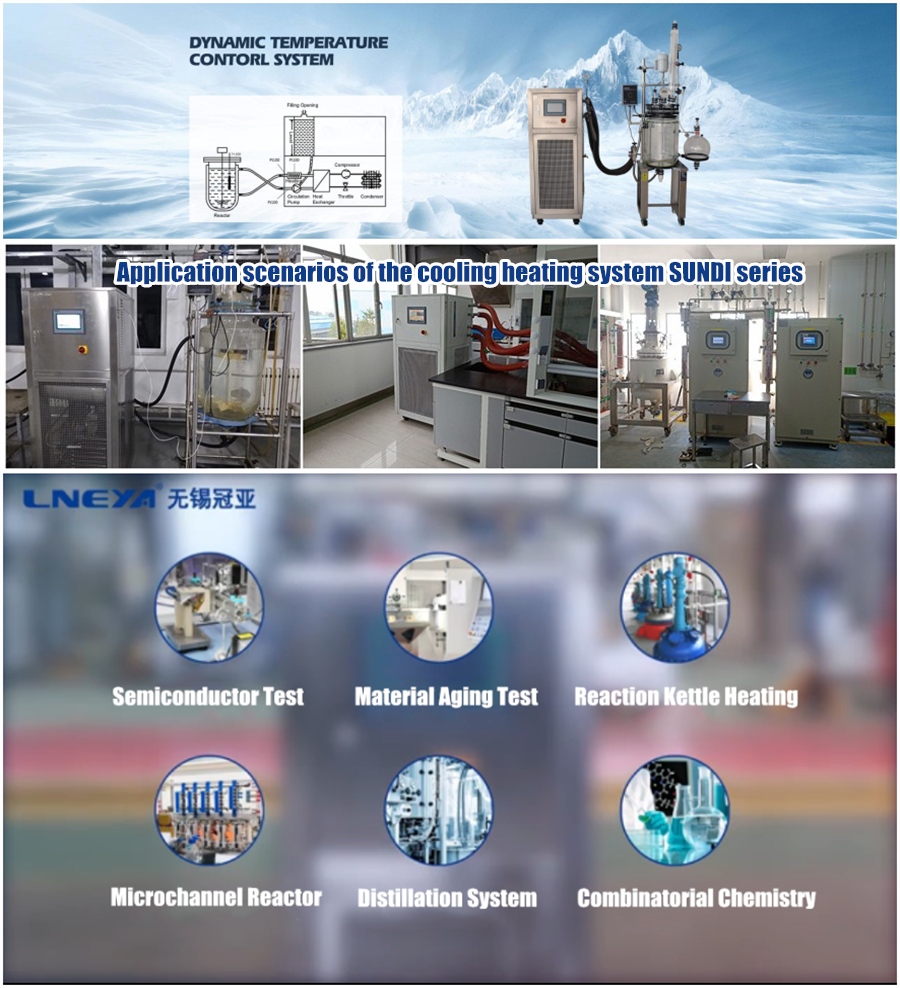

The industrial-grade heating and cooling temperature control system SUNDI series is a device developed and manufactured by LNEYA using its own advantages in the field of cooling, heating and temperature control, and supports customized services in the current technical range and temperature range. If the industrial kettle heating and cooling temperature control system is used, the temperature can be quickly raised or lowered to reach our set value, and the set value and actual value will be d...

Details anzeigen

Failure Analysis of Ultra Low Temperature Chiller Supporting Distillation Equipment

Once the freezer used in the matching distillation equipment fails, we need to solve it in a timely and effective manner to avoid affecting the operation of the entire experiment. In the pharmaceutical, chemical and other industries, low temperature freezers are common equipment and provide a reliable guarantee for various low temperature environments such as pharmaceuticals. In recent years, with the continuous development of the pharmaceutical industry and the continuous improvement of requ...

Details anzeigen

Buy TCU-Multiple Reactor Cooling Heating Temperature Control System

Researchers who do research work know that during the laboratory experiments, TCU-multiple reactors are often used for cooling and heating temperature control systems or high and low temperature all-in-one machines, so TCU-multiple reactions that can provide cold or heat The cooling and heating temperature control system of the kettle has become indispensable. Generally, the cooling and heating temperature control system of the TCU-multiple reaction kettle is used to cool down or constant tem...

Details anzeigen

Reactor temperature control unit TCU with PID control loop

LNEYA reaction kettle temperature control unit tcu adopts PID control loop, which has certain applications in many fields. The reaction kettle temperature control unit tcu of PID control loop adopts fully closed cycle refrigeration system, with fast cooling and heating speed and low noise.The reaction tank temperature control unit tcu of the PID control loop can achieve a dynamic temperature control of -120 degrees to 300 degrees. The system uses existing thermal energy (such as steam, coolin...

Details anzeigenSUNDI Cooling And Heating System-R & D testing of organic synthetic materials and fine chemicals

LNEYA's customer is a research institute engaged in the research, development and production of high-performance, environmentally-friendly new organic materials and fine chemicals.The adhesives produced by customers can be used in integrated circuits, quartz crystals, printed circuit boards, etc .; engineering plastics are used in aerospace, electronics and electrical, precision machinery, office automation equipment, instruments and meters. One of the characteristics of the product is high t...

Details anzeigen

Regelverfahren für Halbleiter-Testkühler zur Erfüllung von Temperaturanforderungen

In der Biopharmazie ist eine hochpräzise Temperatur erforderlich, um die Aktivität von Enzymen und die Herstellung von Produkten zu steuern; in der chemischen Industrie sind bestimmte Temperaturen erforderlich, damit chemische Reaktionen stabil ablaufen; in der Elektronikfertigung muss eine konstante Temperaturumgebung für verschiedene elektronische Komponenten geschaffen werden, damit sie stabil arbeiten und eine bessere Leistung erzielen können, wie z. B. Quarzkristalloszillatoren, elektronische Linearbeschleuniger usw. Obwohl es ...

Details anzeigen

Einsatz von Kälteverarbeitungsanlagen für mechanische Teile und Vergleich mit Flüssigstickstoff

In der Maschinenbauindustrie sind die Qualitätsanforderungen für Teile sehr streng. Um die Leistung der Maschinen zu verbessern und die Produktqualität und -lebensdauer zu erhöhen, wurde eine neue Technologie entwickelt: die Kryobehandlung. Während der kryogenen Behandlung kann der Restaustenit in den Teilen weitgehend in Martensit umgewandelt werden, was die Verschleißfestigkeit, Festigkeit, Zähigkeit und Schlagzähigkeit der Werkstoffe der Teile erhöht, die Ermüdungsfestigkeit verbessert und die...

Details anzeigen

The necessity of temperature heating and cooling cycle in the process of catalytic hydrogenation

In recent years, with the rising price of oil, the demand for benzene obtained from coking benzene has increased, coupled with the country's increasing emphasis on environmental protection, the widespread application of coking benzene hydrogenation technology is imperative. According to the reaction temperature, the coking crude benzene catalytic hydrogenation process can be divided into three types: high temperature hydrogenation (600℃~ 630℃), intermediate temperature hydrogenation (480℃~ 55...

Details anzeigen

Tipps zum Energiesparen für Unternehmen, die industrielle Kühlanlagen einsetzen

Nowadays, energy conservation has been advocated, and power consumption has always been a concern for everyone. Everyone knows that industrial equipment consumes electricity. For many chemical material manufacturing enterprises, the pressure of the chiller's power consumption is not small, so how to save power is the core of this article! Power-saving tips for industrial chiller: First, avoid and reduce the scale of industrial chiller pipeline If the sewage treatment is not done well, calcium...

Details anzeigen

Introduction of distillation principle and temperature cycle control device

Distillation is a common method for purifying liquid substances and separating mixtures. The boiling point of the compound can also be measured by distillation, so it also has a certain significance for the identification of pure liquid organic compounds. The change of saturated vapor pressure of a substance at different temperatures is the basis of distillation separation. Heating the liquid to boiling makes the liquid into a vapor, and then the vapor is cooled and then condensed into a liqu...

Details anzeigen LNEYA Industrial Chillers Manufacturer

LNEYA Industrial Chillers Manufacturer