Flüssigkeitskühlung Chiller

For Energy Storage Cabinet & Charging Pile

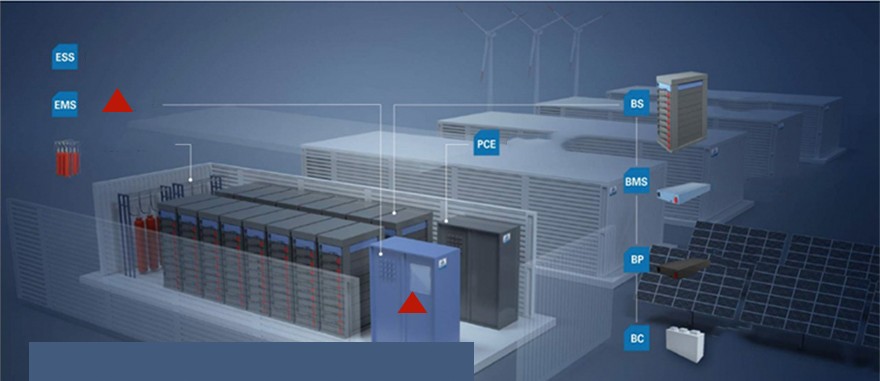

>Liquid Cooling Chiller for Energy Storage Systems(ESS)

Due to the thermal characteristics of batteries, thermal management has become a key link in the electrochemical energy storage industry chain.

The energy storage system generates a large amount of heat and has limited heat dissipation space, making it difficult to achieve temperature control under natural ventilation, which can easily damage the battery’s lifespan and safety.

Ideally, the thermal management design can control the temperature inside the energy storage system within the optimal temperature range (10-35 ° C) for lithium battery operation, and ensure the temperature uniformity inside the battery pack. At present, the mainstream Technology roadmap of thermal management of energy storage is air cooling and liquid cooling.

At present, the proportion of liquid cooling technology in new large-scale storage projects on the power generation side/grid side is rapidly increasing.

Liquid cooling refers to the use of liquid cooling media such as water, mineral oil, ethylene glycol, etc. for cooling. Compared to air cooling, it provides better heat exchange capacity.

Beschreibung des Produkts

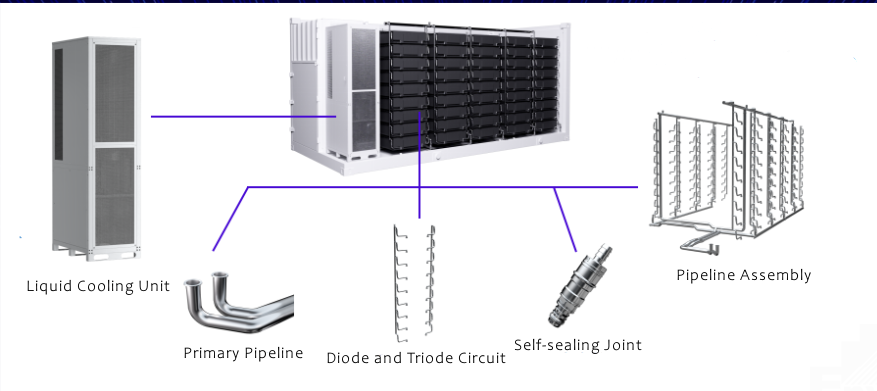

The cooling unit of our LNEYA is air-cooled, water-cooled and liquid-cooled. However, with the development and trend of the industry, liquid cooling will become the mainstream. For this purpose, we have specially developed and produced related series of equipment. According to the needs of use, the environmental use range is -45℃~ 55°C, the refrigeration capacity is accurate at ±0.5°C.

It is an AC power type chiller, which can be left-connected or right-connected, with integrated design, real-time intelligent speed regulation of the fan, and matching with the heat load at all times. High reliability, 365 days of uninterrupted operation, heating capacity of 15kW, meeting the heating needs of low temperature scenarios.

REQUEST MORE INFORMATION

power station liquid cooled chiller

CNYL-45kW

Energy storage cabinet liquid cooling chiller

CNYL-5/8.5kW

Advantages of energy storage liquid cooled temperature control method

- Safety: The energy storage liquid cooling technology has a high content, and the precise temperature control is achieved through the convection of the cooling liquid to achieve efficient heat dissipation, which greatly reduces the risk of temperature out of control and fire;

2. Economy: Energy storage liquid cooling can save 30%-50% energy consumption and reduce operating costs compared with other energy storage systems through heat exchange between refrigerant and battery cells;

3.Energy storage: Compared with traditional air-cooled energy storage systems, liquid-cooled systems are more suitable for large-scale and long-term energy storage.

4. Adapt to harsh environments: It can operate continuously in the natural environment of -45°C~55°C, and upload real-time temperature data to the ESS integrated data center through the Internet.

Usage scenarios

Widely used in energy storage and exchange stations, 1000V600A liquid cooled charging piles, 500KWH, 1000KWH, and 2MWH containers for energy storage containers.

Request a Quote

product videos

Recommended products

Low Temp/Normal Temp Chillers (Biochemistry Pharmaceutical Process)

Temperature Control :-5℃~-150℃

Temperature control for Various reactors, distillation or extraction systems, laboratories, research institutes, chemical, pharmaceutical, petrochemical, biochemical, medical, hospital, research and development workshops, semiconductor testing, aerospace, biology.

Dynamische Temperaturkontrollsysteme (Biochemistry Pharmaceutical Process)

Temperaturregelung: -120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Control Temperature Control Flow Systems(Vehicle/Battery Pack Test)

Temperaturregelung: -40℃~100℃

Temperatur-Simulation für die Qualitätsprüfung von Fahrzeugen: Prüfung der Batterielebensdauer, Einspritzdüsen-/Motorprüfstand, Airbagtest, Komponentenprüfstand, usw. Es kann die externen Umweltbedingungen in der Klimakammer simulieren oder das interne System ersetzen, das die notwendigen tatsächlichen Temperaturbedingungen für den Prüfstand schaffen kann.

Kühlung-Heizung-Systeme (Halbleiterproduktion)

Temperaturregelung: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)

Industrial Chillers Manufacturer Supplier - LNEYA

Industrial Chillers Manufacturer Supplier - LNEYA

Zur Konsultation einreichen

Wir werden Ihnen innerhalb von 24 Stunden antworten